Venus Barlas*, Sahitya Podila and Jens Langsjoen

School of Medicine, Department of Surgery, University of New Mexico Health Sciences Center, Albuquerque, NM, USA

*Corresponding author: Barlas V, School of Medicine, Department of Surgery, University of New Mexico Health Sciences Center, Albuquerque, NM, USA

Introduction

The World Health Organization has reported that manufacturing of personal protective equipment (PPE) must increase by 40 % to meet growing demands. In some hospitals around the world, more than a quarter of the COVID-19 patients are healthcare professionals. Eye protection with either face shields or goggles has been recommended for all healthcare workers involved in the direct contact of patients with COVID-19. By locally manufacturing reusable PPE, we can address potential shortages and protect healthcare workers to reduce the spread of SARS-CoV-2 in hospitals.

Plan

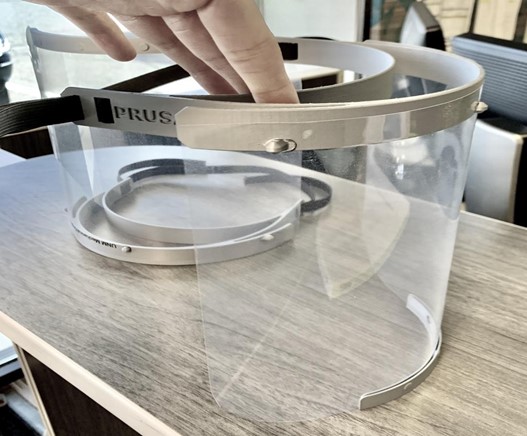

Many 3 Dimensional (3D) printed face shield designs have been shared online and have been approved by the National Institute of Health. One commonly used design is the Prusa Protective Face shield RC3. It is important to collaborate for potential sponsorship to various companies or departments that own Prusa (or other brand) 3D printers at their facilities. Most academic centers have an associated engineering department with a shop or lab that contains 3D printers. Other possible avenues include radiology research departments and local biomedical engineering companies. Next, you should reach out to the facility director with a proposal. It is best to do this after having a specific design in mind with the corresponding files for instructions and coding. Most of the designs involve PLA filament pieces and laser cut sheets. Some of the materials, such as PETG sheets, may be in short supply, and they may have ideas as to what can be substituted and what is available.

Hospitals have some form of Emergency Operations Committee that coordinate their response to the pandemic. This usually includes a safety officer that may have to approve the design and a prototype before moving forward with producing any medical equipment, including face shields. It is helpful to have a physician mentor to connect you with the committee and support your proposal. This group will also be your advocate for coordinating funding towards the project.

Production

It is necessary to print a prototype initially that will be inspected and tested by the institution’s safety officer to ensure that it meets Occupational Safety and Health Administration (OSHA) standards and requirements. This may require several adjustments and prototypes to address all their concerns, so do not get discouraged if the first prototype is not approved. Adjustments may include things like the cut of the shield being too narrow or comfort and adaptation of the elastic strap for different head sizes. After the final prototype is approved by the safety officer, it may also require inspection by the institution’s infection control group. It is their job to assess decontamination methods and the reusability of different parts of the shield. After their final approval and recommendations for decontamination, further adjustments may or may not be made depending on whether disposable or reusable plastic shields are desired.

Usage

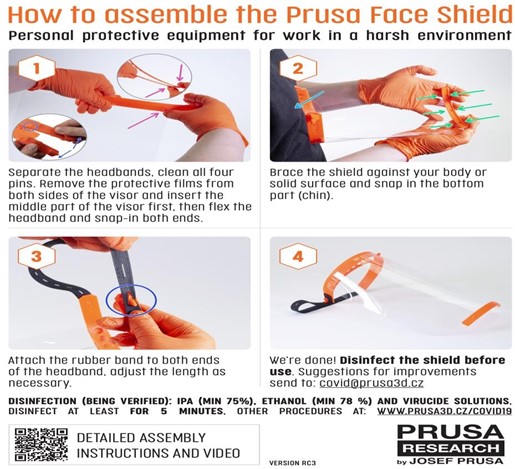

Coordinate distribution of face shields to the hospital staff. Most hospitals have developed recommendations for disinfecting and reusing PPE. The clear sheet may not be as durable as the plastic, so extra sheets should be made to replace the old ones following one to several uses. These are usually low cost such that hundreds of sheets may be used for a handful of shields. When it is time to replace a sheet, users may follow the Prusa Face Shield Assembly Manual (Video) for quick instructions on how to reassemble the face shield.

Figure 1: Prusa Face shield

Figure 2: How to assemble the Prusa Face Shield